Over 3 Gallons of water!

I'm as shocked as you are!

The Case tractor had to be winched onto the tilt bed and winched back off again, and here is the proof. Both back wheels were locked in place, and only the snow and ice helped make possible the movement of the tractor in this condition. The day following their delivery was sunny, and a touch warmer. So I had an opportunity to remove the rear brake housings and check for the locked up brakes I was told this machine suffered from. But first I tried to get the engine running, you know to see if I needed to worry bout anything but removing the new rear tire and parting out the rest of the machine for a little cash to work with.

Well, wouldn't you know, after replacing some clamps and hose, and adding oil and gas and a charged battery, the engine finally started and ran pretty well, without smoke as near as I could tell. It wouldn't idle, and kept stalling as I tried to slow the engine down from a midrange smooth runner to an idling pace. I decided maybe it might be worth some further investment so I took the rear housings off that cover the rear brakes to see how bad they were. They looked like new, and showed no signs of being inoperative at all! I returned to attempting to get the engine to idle, and found the tractor wouldn't even turn over. I removed the starter and found it to be working just fine, though with the weirdest bendix arrangement I've ever seen. I figured I had seized the engine. But before I panicked, I decided to eliminate the problems one at a time. OK maybe I dropped a valve, as it was only three nuts to remove the valve cover, I did. Everything looked fine, and there were signs of proper oiling being experienced. Well, OK, then I seized a piston, I drained the oil and removed the oil pan. It's a 1946 tractor, and the original oil pan isn't rusted out, unlike the 1996 Ford trucks my son and I own, but that's a different rant.... When it finally stopped dripping long enough for me to get under it, I found everything in the engine looking great, and not locked up in any way. I replaced the oil pan, and the oil. I moved to the gear box thinking maybe the shifting forks had slipped allowing two gears to be engaged at the same time. As I raised the top of the gearbox, with the shifter on it, I realized I had bumped the tractor into gear (probably while taking off the brake housings) which was why it couldn't turn over. If I had locked the clutch out, it would have turned over just fine. Of course this little bit of serendipity, removing the gearbox lid, was what allowed me to discover the actual cause of the tractors inability to roll. The inch of ice in the bottom of the gearbox, which is inches above the bottom of the differential, and as they share a common oil galley, that meant there were inches of ice in the differential. After about four hours of pushing and pulling with three vehicles and a cable hoist, I finally got the tractor into the garage, where I started a "four day fire" to thaw out the tractor. Just keeping a fire burning in the garage for four days straight was an ordeal that gives me newfound respect for the people who actually heat their homes, or any other structure with wood.

And, as you can plainly see, I had to rearrange a few things to get the tractor into the garage to be able to heat it up enough to defrost the rear end.

When I realized how much water was going to keep coming out of the rear end of the Case tractor, I slid a catch basin under it just to keep the water from running all over the floor. This turned out to be a good move, as there was a little oily residue as well. I was able to move it out of the garage after only 4 days of thawing out, it rolled pretty well, I'd have driven it but the carb is pretty well screwed up and rather than wear out the starter motor trying to get it going I'm going to rebuild the carb first. The amazing thing is, how much of this old tractor stuff (like a rebuild kit for a 1946 tractor carburetor) is hanging on the wall at Tractor Supply.

When I realized how much water was going to keep coming out of the rear end of the Case tractor, I slid a catch basin under it just to keep the water from running all over the floor. This turned out to be a good move, as there was a little oily residue as well. I was able to move it out of the garage after only 4 days of thawing out, it rolled pretty well, I'd have driven it but the carb is pretty well screwed up and rather than wear out the starter motor trying to get it going I'm going to rebuild the carb first. The amazing thing is, how much of this old tractor stuff (like a rebuild kit for a 1946 tractor carburetor) is hanging on the wall at Tractor Supply.

The Case VAC tractor may be salvageable, or at least more easily saleable, as it may turn out to be restorable. I filled the areas that had been frozen with WD40 to finish getting the water out and protect them until I can get the right oil for it, there doesn't seem to be any lasting damage from the water issues. I am going to look into replacing the damaged gear in the gear box , or I may just weld the missing teeth back in and grind them to shape, I know I can do it, I just wonder what a part might cost, and if it wouldn't be easier to split the tractor and replace it. I once bought an even bigger tractor than this one, It was in three pieces when I had it loaded into my dump truck by the monster front loader at the dump where it was sitting in pieces in the field. I put it back together in my back yard at Lake Street under less than favorable circumstances. It was before I had my garage there, so I used a chain hoist over a limb of the tree in the back yard to hold part of it, and a floor jack rolling on a sheet of plywood to move the rest for reassembly. And I eventually drove it to my dad's house, about 8 miles away, to sell it, from his front yard. Early Sunday morning is the best time to move improperly licensed vehicles in Akron, just thought you might like to know that. It was an Oliver 6 cylinder tractor that I remember being a 9 hundred something, I really had no use for it, and just got it to play with. Would have been good to have now, but I didn't need it then. Which is exactly why I hesitate to consider selling the Case, now that it might be more than parts, and in fact a viable, but ancient, tractor I may have to make it a trade only transaction, I think maybe somebody might want it enough to trade a small Ford or International or Massey Ferguson or even an Oliver for it. Or if I got enough money out of it, I know where there is a 6 cylinder Minneapolis Moline I could pick up reasonably cheap. Oh well, we'll see what happens. They are paid for and don't eat anything so they can just set around for a while, but they will be inside, rather than out in the elements as soon as the ice subsides.

I even bought a pretty good Tech manual for the Frankentractor, and fixed the three point hitch mechanism.

Which lead to my next little project. I looked online to find out what kind of "gizmos" were available for the three point hitch. I found a site with a couple attachments I thought could be very useful. So I hit the scrap pile and came up with this stuff .

Some of which, I turned into this.

Which will be the base for a crane and have various hitch points available to hook things to.

I bought a set of wires and a tune up kit and a rebuild kit for the carburetor, and priced a new radiator and steering wheel for later purchase. Also when I added air to the right rear tire I found it is filled with calcium, at least it bubbled when I added air and the tire valve has a greenish corrosion in it. So it's some form of salt water. I did find out the little rascal doesn't like to climb icy hills, not as sure footed as I had expected. The tires spin pretty easily, but it was a pretty slippery hill I tried to climb. I do have some chains I guess I could put on it, but I don't have a viable plow blade right now so it's no big deal.

As I checked the engine over the other day I noticed a weird thing, the fourth spark plug was attached to a nice rubber boot but no wire. The wire was broken, or cut, at the pipe that the wiring harness runs through, probably more correctly identified as a wire loom. So even though it starts and runs pretty well, the engine was only running on three cylinders. I decided to rewire it tonight, again not an easy job considering what works on me and doesn't. With the gas tank right over the engine, it was like reaching into the refrigerator to try to get something in the back, not easy. I finally did get it done and it started and ran even smoother than before, not that surprising I guess. It did remove some of the unburned gasoline smell from the exhaust but it still smokes a little and will need to be "re ringed" but that will be next winter at the earliest.

The Frankentractor has been switched to 12 volts, which basically means it has a resistor in the line for the coil, and the starter turns pretty quickly and shouldn't be engaged for too long at a time. As the lights are missing and they didn't have radios on their tractors in the 40's there's really not much else affected. So at this point, everything I bought it for works.

The engine originally had a coil mounted on the front of the block next to the water pump and surrounded by belts, pulleys and hoses. Though this seems a silly place to put an electrical part, it is the first thing cooled by the fan, after, of course, pulling the air through the radiator. OK maybe not the most sensible placement. And it is a bugger to get to to set the points, nearly requiring the removal of the radiator to gain access. Oops did I neglect to mention that the distributor cap is there on the front of the engine as well, OK here's the thing, it is a great place in regards to the connection of the points, and the rotor, directly to the end of the camshaft. Every other aspect of it is wrong, or has a much better option for placement on the engine. Particularly regarding accessibility. This original design was shown to be lacking, by the later placement of the distributor on the right side of the engine in subsequent models.

Now that being said, I have ordered a new 12v coil to replace the 6 volt module that has been bastardized to allow the connection of a separate 12 volt coil that is mounted on the side of the block near the carburetor. Rather an ingenious modification, I'm guessing to avoid paying the "Ford" price for the new coil, which is over 40 dollars. Quite a chunk of change, considering I can buy a new "Autozone 12 volt coil" for 10 dollars. And I bought a new battery. Come on something deserves a new battery around here, besides the Motor Home, which I can't use at present. And it takes 4 new ones, the big expensive type.

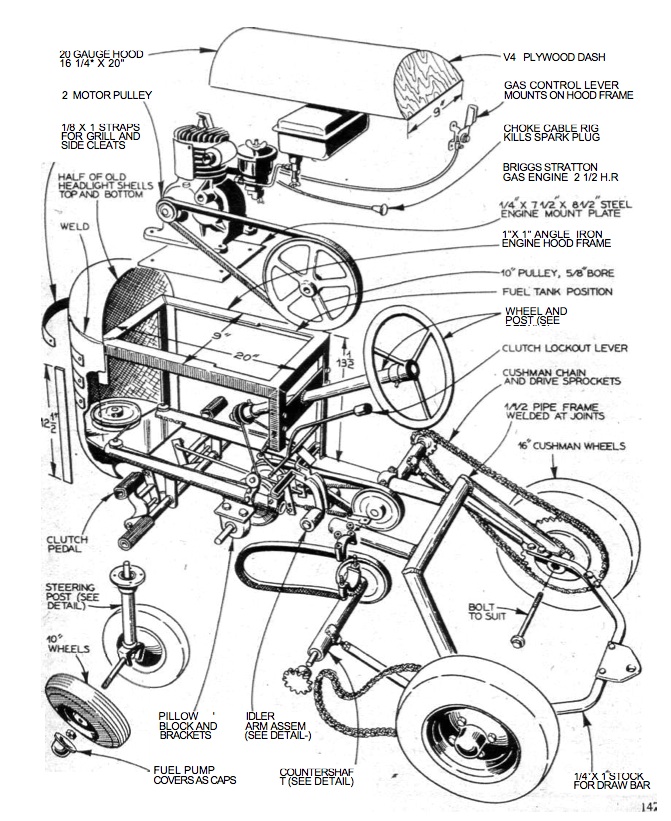

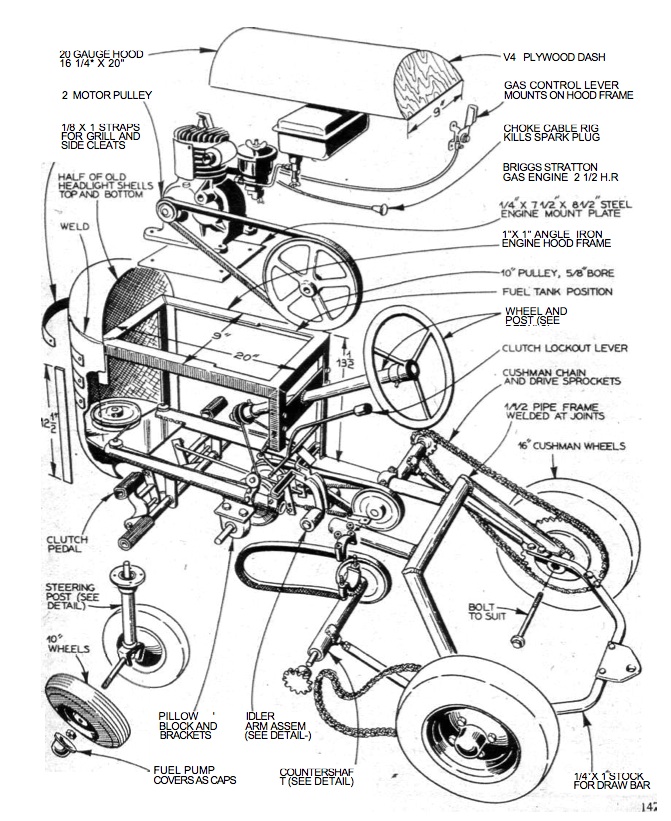

So back to the tractors. This is going to start to be like the garage pages, I feel it already. Garage, Garage, Garage. Tractor, tractor, tractor. Geez get a life! So anyway about the tractors. I think the Case VAC is a possible keeper. Chris will be so surprised. OK, here's why. I had thought that I wouldn't be able to find a tractor, for a reasonable price, that would do what I needed to do. So I had downloaded and started collecting parts to build, well this!

I guess they used to call them doodle bugs. And they were supposed to be home built and very powerful, and everybody who built one had amazing stories of all they could do, with a 2 1/2 horse engine. After reading about some of them, I might just build one to be able to experience the amazing things they can do. Well anyway, the Case is a real tractor and rated at about 16 HP. The Ford is rated about 27 HP max... Obviously better than a 2 1/2 HP home built. But the "home built" could be fun anyway.

So after all that, I decided I still needed to get the new tires on the Frankentractor. Having never changed a tire this size, I thought, well sure I can do it, I have tire spoons. And I did do it but it took days, and muscles I haven't used for quite a while, I'd say never, but I know I've felt these pains before. I just wanted to never enjoy them again. Ah the thrills of mechanical enterprise. At times I feel like I'm reinventing the world of struggle, or actually a pioneer in a way. Now, not like my friend, John who is basically self sufficient after 3 years of living in Tennessee. I'm struggling through the birthing pains of the industrial revolution, Yeah I guess I'm reinventing the wheel again. Though I have electric welders and a plasma torch and oxyacetylene to help. I suppose I'm cheating a little. Anyway back to the tires. The tires were literally rusted to the rims, I had to wedge the rubber loose every inch of each bead. That took a lot of hammer action, and I've got no shoulders. That was the first day. After I got the tire off one side of the rim on the Case tractor I realized the rim had to come off anyway. I'd done it on the tractor just to make holding it easier, and spinning it possible.

Well when I took the rim off the hub, or center, I'm unsure of the correct terminology, I found that the tire was much easier to get off the other side of the rim, due to the design of the rim. Check this out. Where you see the yellow arrow is a depression I didn't notice, talk about depressed. I took the tire off the hard side first! Probably most intelligent people would tell you, "you can't take the tire off the wrong side of the rim there isn't room to do it, and the bead won't stretch". Well they're smarter than me, and wrong, Cause with enough force I can do anything, just ask my aching muscles and tendons and I'm sure a bone or two was involved. So I decided to take this side off the easy side and just rotate the rim and pull it out. Okay, if you have any idea what I just said, you know where this is going and it ain't pretty!

Well when I took the rim off the hub, or center, I'm unsure of the correct terminology, I found that the tire was much easier to get off the other side of the rim, due to the design of the rim. Check this out. Where you see the yellow arrow is a depression I didn't notice, talk about depressed. I took the tire off the hard side first! Probably most intelligent people would tell you, "you can't take the tire off the wrong side of the rim there isn't room to do it, and the bead won't stretch". Well they're smarter than me, and wrong, Cause with enough force I can do anything, just ask my aching muscles and tendons and I'm sure a bone or two was involved. So I decided to take this side off the easy side and just rotate the rim and pull it out. Okay, if you have any idea what I just said, you know where this is going and it ain't pretty!

Well by applying a Herculean amount of power, which I only had due to pills and cold, as my body gets numb after a few hours in the 40's in a "T"shirt, because the sweat was rolling off me as I got more and more determined that the wheel was going to come out of the tire, it was no longer a bead or two in the rim, it was the rim completely trapped within the tire, I finally managed to get the tube out, before it had been sliced and diced, but having the rim entirely within the confines of the tire was new to me, never done it before, hope never to do it again!

Even after a free CATSCAN, I was still sunk. There is literally no where to start, particularly because I couldn't hold, lift, or pull on anything, without the rim simply shifting inside. Not a good situation. So I finally got out tools that aren't recommended for tire work. Pry bars, crowbars and clamps, and working with both arms, both knees, and my chin, which is connected to all those other parts through screws and plates in my neck so it makes me real nervous to even attempt it. I finally got the rim started out of the tire. But I didn't enjoy it. Now there is a serious dearth of pictures of this process. First I was busier than a one armed paperhanger, maybe even a one legged indian in an ass kickin contest, and documenting this size of a screw up wasn't a priority. And if I'd died doing it, it would have taken Sherlock Holmes to figure out how I got that many pieces of metal in all those places without a fencing team there to have impaled me.

But I did get a picture of some of them, after using them to get the second tire off. Though this is a Ford rim which is the same either direction, so I couldn't do this one wrong, that I'm aware of. Give me time, I'll find a way.

I used the garage door to hold the tire upright while I removed the tube. It saved me trying to put it back on the tractor, as I was kind of "tired" at this point, and needed both hands to try to pull the rusted tube off the rim, and get it out of the tire at the same time. I even used the tire itself to rub and roll the tube off the rim, kind of like a rounded scraper.

The tubes had been filled with calcium, at times in the past, now these are tubed tires and some past owner had "plugged" a leak in one tire so the tube was stuck to the tire and the rim at one point. It may have slowed the air leak, but it definitely hastened the rust of that rim, as the Calcium Chloride which is about the same as table salt (Sodium Chloride) leaked into the rim area and rusted things really well. I'm guessing that's why I had to chisel the tire off that rim.

SO in an attempt to leave things better than i found them and to make it last a little longer for me, I painted the rim before I put the newer tire on the Frankentractor. You know once you start wire brushing and painting things it gets crazy and it's all you want to do, NOT!

This is the original tread pretty well rounded, but with a good tread depth. Of course the rubber is at best, weather checked, and just plain cracked in some areas. But the interior appears intact and after I repair the tube and paint the rim, It is going back on the Case for now.

This is the newer tire. It still has the size showing on the top of the treads. And they are sharp and should bite well, I have already found they aren't much good on ice, even with the right rear tire still loaded with calcium. The little tractor just sits and spins, Though I did learn a braking trick, while driving it up the ice covered driveway. Apply the brake to the spinning tire (each rear wheel has a separate brake, for any of you city folk, tee hee) and when you slow the spinning tire, the other tire might get some traction and keep you moving. Probably where they got the idea for positraction.

And this is the Frankentractor with the new treads on both back rims.

This is an idea I had for a new grill. The tractor currently has none, and I'm not going to parade the thing. But it does need something to keep the bigger weeds and sticks from messing up the radiator, and with nothing there, it reminds me of the IRONMAN suit in the movie. Now I thought I had a great idea, and that I should start making faces to go on the fronts of tractors, like for parades and such, but Thomas the Tank Engine sort of already did that. And I've got enough to do already.

This page got pretty long, so I'm saving the great winter pictures for the next one. The ice and snow are incredible. The landscape looks so different, in one way you can see so far into the treed areas, and in another the sun glinting off the ice makes everything appear like a glass blowers dream.. And I don't have to go anywhere if I don't want to, just walk out and look for a while or take a walk into the woods. Wow, it's great. OK one picture! The hay field.

And these two, just because.

And believe it or not, these are full color pictures.

Man, are we happy out here!

The Chores, Fresh Air, Green Acres is for ME.

The happy Nada Farmer, wondering about the inscrutable technology of last century. Totally unbelievable that people survived with this stuff through tough times and raised food and kids. When did they have the time for anything, or the energy to create the next generation? Just heating the garage is a full time job! Isn't ignorance Bliss? I'm pretty certain, it's the pills....

The happy Nada Farmer, wondering about the inscrutable technology of last century. Totally unbelievable that people survived with this stuff through tough times and raised food and kids. When did they have the time for anything, or the energy to create the next generation? Just heating the garage is a full time job! Isn't ignorance Bliss? I'm pretty certain, it's the pills....

When I realized how much water was going to keep coming out of the rear end of the Case tractor, I slid a catch basin under it just to keep the water from running all over the floor. This turned out to be a good move, as there was a little oily residue as well. I was able to move it out of the garage after only 4 days of thawing out, it rolled pretty well, I'd have driven it but the carb is pretty well screwed up and rather than wear out the starter motor trying to get it going I'm going to rebuild the carb first. The amazing thing is, how much of this old tractor stuff (like a rebuild kit for a 1946 tractor carburetor) is hanging on the wall at Tractor Supply.

When I realized how much water was going to keep coming out of the rear end of the Case tractor, I slid a catch basin under it just to keep the water from running all over the floor. This turned out to be a good move, as there was a little oily residue as well. I was able to move it out of the garage after only 4 days of thawing out, it rolled pretty well, I'd have driven it but the carb is pretty well screwed up and rather than wear out the starter motor trying to get it going I'm going to rebuild the carb first. The amazing thing is, how much of this old tractor stuff (like a rebuild kit for a 1946 tractor carburetor) is hanging on the wall at Tractor Supply.

Well when I took the rim off the hub, or center, I'm unsure of the correct terminology, I found that the tire was much easier to get off the other side of the rim, due to the design of the rim. Check this out. Where you see the yellow arrow is a depression I didn't notice, talk about depressed. I took the tire off the hard side first! Probably most intelligent people would tell you, "you can't take the tire off the wrong side of the rim there isn't room to do it, and the bead won't stretch". Well they're smarter than me, and wrong, Cause with enough force I can do anything, just ask my aching muscles and tendons and I'm sure a bone or two was involved. So I decided to take this side off the easy side and just rotate the rim and pull it out. Okay, if you have any idea what I just said, you know where this is going and it ain't pretty!

Well when I took the rim off the hub, or center, I'm unsure of the correct terminology, I found that the tire was much easier to get off the other side of the rim, due to the design of the rim. Check this out. Where you see the yellow arrow is a depression I didn't notice, talk about depressed. I took the tire off the hard side first! Probably most intelligent people would tell you, "you can't take the tire off the wrong side of the rim there isn't room to do it, and the bead won't stretch". Well they're smarter than me, and wrong, Cause with enough force I can do anything, just ask my aching muscles and tendons and I'm sure a bone or two was involved. So I decided to take this side off the easy side and just rotate the rim and pull it out. Okay, if you have any idea what I just said, you know where this is going and it ain't pretty!