ray...

The happy Nada Farmer, yeah, whatever ... too busy to deal with all this right now!

The happy Nada Farmer, yeah, whatever ... too busy to deal with all this right now!

Keep coming back, page Sixty Two follows......soon.

NadaFarm Chronicles

************************************************If this line is straight it is the proper page width***********************************************

As we learned in the last installment the highly experienced and profoundly capable Repower Company with their 50 years of experience and unlimited resources was" ready to give up" after the first letter I sent. Now you may think I'm making this up, but here's the promo on their website about their incredible.... well, you read it.

( This is the second letter, after his "redlined response on each item." ready to take the unit back rahter than have to deal with any real questions.... )

Ask Rick

Do you have a seemingly impossible problem with an out-of-date or discontinued engine? Try me for the answer. The service is free and I look forward to a challenge! While I might not know everything about engines, I'm certainly no slouch on the subject. I've been working in the industry for more than 50 years. In addition, I have almost unlimited resources and I know how to use them, so Now is the time to "Ask Rick".

We at Repower Specialists, Ltd. intend to insure your complete satisfaction with our products. Please contact me or any of our other specialists with questions regarding our kits. Whether it be installation, performance, warranty, or any other aspect, we are happy to help. Your comments, good or bad, are welcomed. Our reaction to your criticism will result in a better product for the future. Of course, we like to hear the good things too. Please be sure to provide us with your suggestions for possible future kits.

Phone: ***-XXX-XXXX.

YOU sure seem willing to give up quick, you did write this, right?

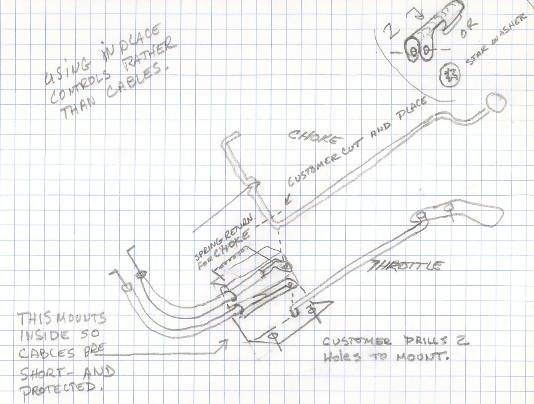

Attached is an idea for the use of the original control rods. with your "almost unlimited resources", I'll bet you can find something like it already available.

Still a "frog strangler outside" so I will have to get back to you on the hydraulic couplings/90's , and the dimensions required for the " 4 bend pipe" for the muffler, to route it through the original hole.

My letter to Rick,

HIS responses

and my responses to his responses...

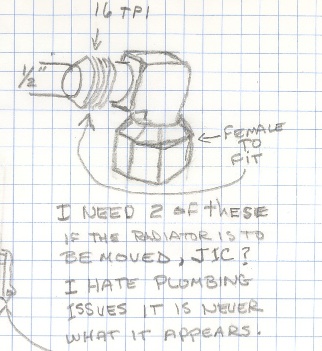

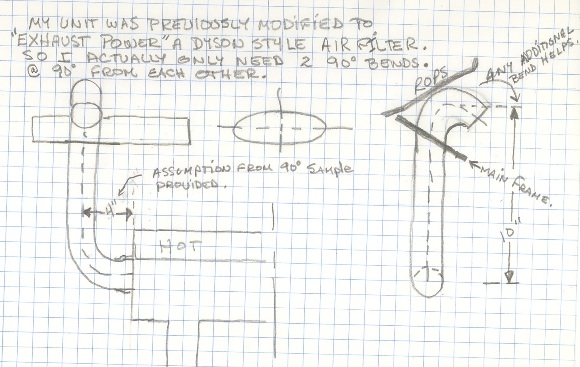

Items required, a 90º elbow to replace the Honda engine drain plug, a length of pipe and a cap to extend the oil drain operation 7 1/2 inches from the centerline of the engine to clear the rear of the machine. We will be sending an oil drain hose. It is 11” long plus fittings. I have left the plug end fitting uninstalled so that you may cut this to length. You will have to heat the hose with a heat gun and insert the fitting. (KEEP THE HOSE I won't trust the entire life blood of the engine to an "in place hose", and anyone that would, shouldn't be allowed around machinery.) 2 ( 1/2 inch male to 1/2 inch female 90º JIC hydraulic fittings) to lay hoses along top of hydraulic oil radiator. These have been ordered. I expect them to come in later today. The adapter from 1/8 inch steel control rods to cable interfaces, when you find them. We will not be addressing the control group of this kit. Honda specified cable controls. The cable controls, provided with the kit, are fully functional and approved by Honda for the application. (very disappointing!) At least the minimal exhaust pipe 90 by 90 by 90 in the attached drawing. We do not have bending capability. I have included three 90 degree elbows, straight tube and appropriate clamps to accomplish what you have drawn I also noticed there is no clamp to affix the exhaust pipe extension, or even a self tapping screw to hold it in place.

Tomorrow I will be cutting new louvers in the rear door and attempting to move the 40 year old plastic shroud so the airflow over the hydraulic radiator, and it's effectiveness isn't lost. YOU really have never been asked about this before?

In the future should you decide to include the 6 prong plug pair with pigtails, to clean up the installation. You could send me a set. I need clarification on this one. There are only two or three wires that need to be connected at the engine. Why an 8 cavity connector? The original engine and monitoring panel was connected with a "two over six connector" this allowed the generator to be monitored, the engine to be started and the oil pressure to be monitored. So I suggested a 6 cavity connector. And anything is better than the mess I'm looking at.

Let me know when these parts will be sent, or if you have discovered a more reasonable way to accomplish this, without disassembling the entire rear door and cutting and bending new louvers.

Ray McCune.

Ray,

OK, I’ll forget the hose. Do you want the fittings then? I really don’t understand your position on this. Your hydraulic lines are hose and under extreme pressure to boot.

We’ll fabricate a 6 cavity plug. I still don’t understand how you can use six positions at the engine. Other than at the engine, the Bobcat wiring remains intact.

Rick

Rick

When a hydraulic line bursts, which is rare, because they are manufactured for stress from motion, oil resistance, and pressure. They have braided internal reinforcement. And when a hydraulic hose breaks if you aren't cut by the pressure release, burned by the hot hydraulic fluid, or crushed or trapped due to a load shift, big deal, the machine stops doing what you want. But if a little rubber hose, leaks, falls off, or is caught and pulled off, while the engine is running, the resultant loss of oil is catastrophic, particularly to an air cooled, aluminum engine, mounted out of sight, and with only an oil sensor light that may or may not warn in time, or be immediately noticed. I'm sure a loss of oil due to failure of a hose permanently installed in the drain screw hole, would be a tough sell to HONDA on a three year warrantee claim. In this application, nothing less than brass or steel tubing should even be attempted. As far as the fittings, please just send the fitting that screws into the block, so I can properly fabricate what should be in that location.

Thanks for the electrical connectors.

Ray...

Well this is getting boring, and the rest of the job was just me doing what I always do, making it work the NadaFarm way. I think the guy kept his temper pretty well, but he was thick about a couple issues. And obviously, didn't really want a challenge, or to do it the best that he could. I know he has to make money, but he sure talks a better operation than he provides, just another case of be careful who you buy from, but then how can you check these guys out without knowing someone who has dealt with them before? And how many "40 year old Bobcat repowers" do you know people doing, that you can ask about the efficacy of the "KIT" that they promise?

So here's how I fixed the oil cooler problem, about two weeks before they finally sent the parts to do it their way. I like mine better. Besides, I realized I couldn't really have cut more louvers and had them look decent anyway. That plate is way too thick for manipulating properly with hand tools. Soooo.....

I used my favorite cutting tool, the plasma torch, to remove the louvered area of the back door. Because I realized that if I just cut it out and turned it over it would move the original holes to the place I need the oil cooler to move to, and the louvers would even be in the correct orientation, per the original design, from Melroe. I did lose the BOBCAT logo, (well not really, it is upside down inside the door) So now I have to tell people looking at it from the back it is indeed a "real" bobcat loader. But then, nobody usually asks me.

I Mig welded the plate back in, effectively moving the oil cooler up the back door over 5 inches and maintained the louvers for proper cooling, but the REALLY COOL PART is how I solved the ridiculous "hoses won't fit in the door anymore", problem...

I turned the cooler upside down, which ran the hoses up from the bottom! Now the hoses are hooked up just as before, no extra fittings, and they lay quite nicely in the center of the rear door. I did have to cut a rhombus out of the metal shield that protects the cooler from the engine compartment, but I was able to maintain all the original parts and the original design for cooling. And the engine is in place to utilize the remainder of the cowling to help cool the hydraulic oil radiator.

I still have to build the adapter for "the cables to rods" described above and install the electrical plug he finally sent. I was just shocked at how quickly they folded under the least questioning about thier level of expertice, of course they probably don't get many real suggestions to make their kits better, most farmers just throw the engine in, after pounding and then welding the improperly machined coupling on, and suffer silently for about two months, until the overheated oil finishes ruining the pump and they toss the entire unit and go buy a new one. Unfortunately, I am not in a position to write off the loss, like a real farm might, I have to get another thirty years or so out of this baby. So all in all it took about a month to get it all to this point, and would have taken another two weeks to get the final fittings, which eventually came. But, thanks to the plasma torch, I didn't need them by then.

I'll have a couple more little upgrade issues to deal with this winter in the garage, don't tell Chris, but the new garage is going to ease the crowding in my garage, she thinks I'm not going to have anything in HER garage.... Of course, that's another page, as it is mid June and the geniuses we ordered the building from, haven't even sent me drawings for the footer yet! Can an idiot in charge of a country possibly excuse the total lack of responsibility and expertise in all fields? I'm starting... no I'm completely convinced, that we are doomed, there seems to be no "absolute criteria" for anything and obviously no sense of pride in doing a good and complete job of anything.... and excellence in a field? Well, a man outstanding in his field, is a farmer taking a break.

I'm going to start a doom and gloom page just for the questions I can't find answers for today, look for it in future editions.

Meanwhile, back at the farm... free energy, self sufficiency, talapia, all in a small garden. Yes it can be done, but I can't get far enough ahead on mowing the lawn, to get to it. When I consider the guy who showed up with a shovel, an axe, and a couple draft animals, and began clearing an area to build a house out of the logs he just removed... He created it all with his little axe. Wow, what a guy he was. No wonder they all died at 45.

The happy Nada Farmer, yeah, whatever ... too busy to deal with all this right now!

The happy Nada Farmer, yeah, whatever ... too busy to deal with all this right now!

Keep coming back, page Sixty Two follows......soon.